Latest cement resistor specifications

Cement resistors are commonly used electronic components that are used to limit current, regulate voltage, and perform voltage division functions in circuits. With the continuous development of technology, the specifications of cement resistors are constantly being updated and improved. The latest specifications for cement resistors require the following characteristics:

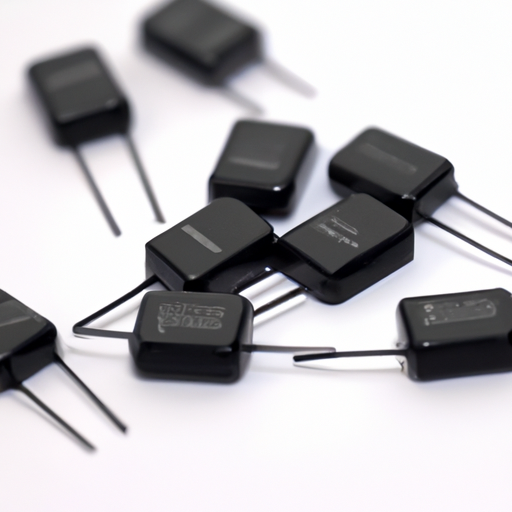

Secondly, the latest specifications for cement resistors require higher accuracy and stability. In modern electronic devices, the requirements for circuit accuracy and stability are increasing, making the accuracy and stability of cement resistors a key indicator. The latest specifications for cement resistors require strict control of various parameters in the design and production process to ensure that the product has higher accuracy and stability.

Additionally, the latest specifications for cement resistors also require better heat dissipation performance. With the increase in power of electronic devices, resistors generate a large amount of heat during operation. Poor heat dissipation can affect the stability and lifespan of the product. Therefore, the latest specifications for cement resistors require that heat dissipation be considered in the design and manufacturing process, using better heat dissipation materials and structures to ensure effective heat dissipation and maintain a stable operating state.

Lastly, the latest specifications for cement resistors also require better environmental performance. With the increasing awareness of environmental protection, the environmental requirements for electronic products are also increasing. The latest specifications for cement resistors require that environmental pollution be minimized in the design and manufacturing process, using environmentally friendly materials and processes to ensure that the product meets environmental standards.

In conclusion, the latest specifications for cement resistors require higher requirements in terms of voltage resistance, heat resistance, accuracy, stability, heat dissipation performance, and environmental performance to meet the higher requirements of modern electronic devices for resistors. Only by continuously improving the quality and performance of products can we better meet market demands and drive the development of the electronic components industry.

Cement resistors are commonly used electronic components that are used to limit current, regulate voltage, and perform voltage division functions in circuits. With the continuous development of technology, the specifications of cement resistors are constantly being updated and improved. The latest specifications for cement resistors require the following characteristics:

Secondly, the latest specifications for cement resistors require higher accuracy and stability. In modern electronic devices, the requirements for circuit accuracy and stability are increasing, making the accuracy and stability of cement resistors a key indicator. The latest specifications for cement resistors require strict control of various parameters in the design and production process to ensure that the product has higher accuracy and stability.

Additionally, the latest specifications for cement resistors also require better heat dissipation performance. With the increase in power of electronic devices, resistors generate a large amount of heat during operation. Poor heat dissipation can affect the stability and lifespan of the product. Therefore, the latest specifications for cement resistors require that heat dissipation be considered in the design and manufacturing process, using better heat dissipation materials and structures to ensure effective heat dissipation and maintain a stable operating state.

Lastly, the latest specifications for cement resistors also require better environmental performance. With the increasing awareness of environmental protection, the environmental requirements for electronic products are also increasing. The latest specifications for cement resistors require that environmental pollution be minimized in the design and manufacturing process, using environmentally friendly materials and processes to ensure that the product meets environmental standards.

In conclusion, the latest specifications for cement resistors require higher requirements in terms of voltage resistance, heat resistance, accuracy, stability, heat dissipation performance, and environmental performance to meet the higher requirements of modern electronic devices for resistors. Only by continuously improving the quality and performance of products can we better meet market demands and drive the development of the electronic components industry.