What is the Mainstream Production Process of Sensitive Resistors?

I. Introduction

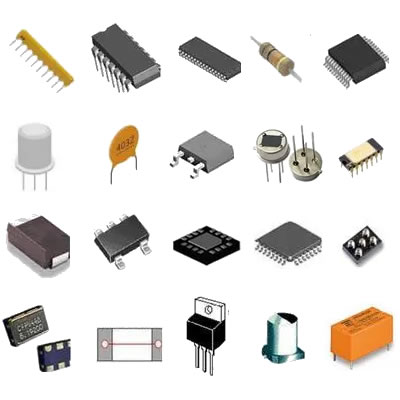

Sensitive resistors are crucial components in modern electronic devices, playing a vital role in sensing and measurement applications. These resistors respond to changes in environmental conditions, such as temperature, light, and mechanical stress, making them indispensable in various industries, including automotive, healthcare, and consumer electronics. This blog post will explore the mainstream production process of sensitive resistors, detailing the types, raw materials, fabrication techniques, and innovations shaping their manufacturing.

II. Types of Sensitive Resistors

Sensitive resistors come in various forms, each designed for specific applications. The three most common types are thermistors, photoresistors, and strain gauges.

A. Overview of Different Types of Sensitive Resistors

1. **Thermistors**: These temperature-sensitive resistors exhibit a significant change in resistance with temperature variations. They are widely used in temperature sensing and control applications, such as in thermostats and temperature compensation circuits.

2. **Photoresistors**: Also known as light-dependent resistors (LDRs), photoresistors change their resistance based on the intensity of light falling on them. They are commonly used in light-sensing applications, such as automatic streetlights and camera exposure controls.

3. **Strain Gauges**: These resistors measure the amount of deformation or strain in an object. Strain gauges are essential in structural health monitoring, load cells, and various industrial applications where stress analysis is critical.

B. Applications of Each Type

Each type of sensitive resistor has unique applications. Thermistors are crucial in medical devices for monitoring body temperature, while photoresistors are used in consumer electronics for automatic brightness adjustment. Strain gauges find applications in aerospace and civil engineering, where they help monitor the integrity of structures under stress.

III. Raw Materials Used in Production

The production of sensitive resistors involves various raw materials, each contributing to the performance and reliability of the final product.

A. Conductive Materials

1. **Metal Oxides**: Metal oxides, such as tin oxide and nickel oxide, are commonly used in thermistors and photoresistors due to their semiconducting properties. These materials exhibit a significant change in resistance with temperature or light intensity.

2. **Polymers**: Conductive polymers are increasingly used in sensitive resistors, particularly in flexible electronics. They offer advantages such as lightweight, flexibility, and ease of processing.

B. Substrates

1. **Ceramic**: Ceramic substrates are often used for thermistors due to their thermal stability and insulating properties. They provide a robust base for the sensitive resistor elements.

2. **Glass**: Glass substrates are used in photoresistors, offering excellent transparency and chemical resistance, which is essential for light-sensing applications.

C. Other Materials

1. **Adhesives**: Adhesives are used to bond different components of sensitive resistors, ensuring structural integrity and reliability.

2. **Coatings**: Protective coatings are applied to sensitive resistors to enhance their durability and resistance to environmental factors, such as moisture and dust.

IV. The Production Process

The production of sensitive resistors involves several key stages, from design and prototyping to testing and quality assurance.

A. Design and Prototyping

1. **Initial Design Considerations**: The production process begins with the design phase, where engineers consider the specific requirements of the sensitive resistor, including its intended application, sensitivity, and environmental conditions.

2. **Simulation and Modeling**: Advanced simulation tools are used to model the behavior of the resistor under various conditions, allowing for optimization before physical prototypes are created.

B. Material Preparation

1. **Sourcing and Quality Control of Raw Materials**: High-quality raw materials are essential for producing reliable sensitive resistors. Manufacturers establish strict quality control measures to ensure that all materials meet industry standards.

2. **Pre-processing of Materials**: Raw materials undergo pre-processing, such as grinding, mixing, and drying, to prepare them for fabrication.

C. Fabrication Techniques

1. **Thin-film Deposition**: This technique involves depositing thin layers of conductive materials onto substrates. Two common methods are:

- **Physical Vapor Deposition (PVD)**: A vacuum process that involves vaporizing a solid material and depositing it onto the substrate.

- **Chemical Vapor Deposition (CVD)**: A process that uses chemical reactions to produce thin films on the substrate.

2. **Screen Printing**: This method involves applying conductive inks onto substrates through a mesh screen, allowing for the creation of intricate patterns and designs.

3. **Laser Cutting and Etching**: Laser technology is used to cut and etch materials with high precision, enabling the production of complex shapes and features in sensitive resistors.

D. Assembly

1. **Mounting on Substrates**: Once fabricated, sensitive resistors are mounted onto their respective substrates, ensuring proper alignment and stability.

2. **Interconnections and Soldering**: Electrical connections are made through soldering, ensuring that the sensitive resistor can interface with other electronic components.

E. Testing and Quality Assurance

1. **Electrical Testing**: Each sensitive resistor undergoes rigorous electrical testing to ensure it meets performance specifications, including resistance values and response times.

2. **Environmental Testing**: Resistors are subjected to various environmental conditions, such as temperature and humidity, to assess their reliability and durability.

3. **Compliance with Industry Standards**: Manufacturers ensure that their products comply with relevant industry standards, such as ISO and IEC, to guarantee quality and safety.

V. Challenges in Production

The production of sensitive resistors is not without its challenges.

A. Material Limitations

The availability and properties of raw materials can limit the performance and application of sensitive resistors. Manufacturers must continuously seek new materials that offer improved sensitivity and stability.

B. Precision in Fabrication

Achieving high precision in fabrication is critical for the performance of sensitive resistors. Variations in dimensions or material properties can lead to inconsistent performance.

C. Cost Management

Balancing quality and cost is a significant challenge in the production process. Manufacturers must find ways to optimize production efficiency while maintaining high standards.

D. Environmental Considerations

As environmental regulations become stricter, manufacturers must adopt sustainable practices in their production processes, including waste reduction and energy efficiency.

VI. Innovations in Sensitive Resistor Production

The field of sensitive resistor production is evolving, driven by advancements in technology and materials science.

A. Advances in Materials Science

Research into new materials, such as nanomaterials and composites, is paving the way for the development of more sensitive and reliable resistors.

B. Automation and Industry 4.0

The integration of automation and smart manufacturing technologies is enhancing production efficiency and precision, allowing for real-time monitoring and quality control.

C. Sustainable Production Practices

Manufacturers are increasingly adopting sustainable practices, such as recycling materials and reducing energy consumption, to minimize their environmental impact.

VII. Conclusion

The production process of sensitive resistors is a complex and multifaceted endeavor that involves careful consideration of materials, fabrication techniques, and quality assurance. As technology continues to advance, the future of sensitive resistor manufacturing looks promising, with innovations in materials science and production practices driving improvements in performance and sustainability. Sensitive resistors will continue to play a crucial role in advancing technology, enabling new applications and enhancing the functionality of electronic devices.

VIII. References

- Academic journals on materials science and electronic components.

- Industry reports on the latest trends in sensor technology.

- Books on electronic components and materials science for further reading.

This comprehensive overview of the production process of sensitive resistors highlights their significance in modern electronics and the ongoing innovations that will shape their future.