What are the Product Standards for Resistor 2?

I. Introduction

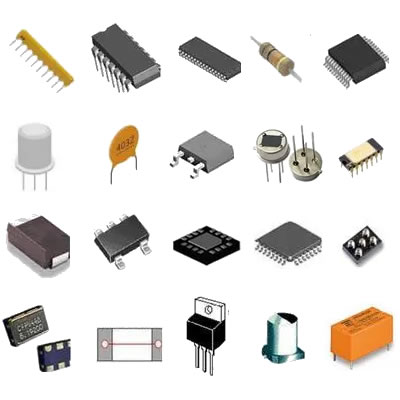

Resistors are fundamental components in electronic circuits, serving the crucial role of controlling current flow and voltage levels. They are essential for the proper functioning of various electronic devices, from simple household appliances to complex industrial machinery. As technology advances, the demand for reliable and high-quality electronic components has increased, making product standards more important than ever. These standards ensure that components meet specific criteria for safety, performance, and compatibility, ultimately enhancing the reliability of electronic systems. This article aims to explore the product standards for Resistor 2, a specific type of resistor that plays a vital role in modern electronics.

II. Understanding Resistor 2

A. Definition and Characteristics of Resistor 2

Resistor 2 is a type of resistor characterized by its specific resistance value, tolerance, and power rating. Unlike standard resistors, Resistor 2 may have unique features such as temperature coefficients, which indicate how its resistance changes with temperature. These characteristics make Resistor 2 suitable for particular applications where precision and stability are critical.

B. Common Applications of Resistor 2 in Electronic Devices

Resistor 2 is commonly used in various electronic applications, including signal processing, voltage division, and current limiting. Its precision makes it ideal for use in sensitive circuits, such as those found in medical devices, telecommunications equipment, and automotive electronics. The ability to maintain consistent performance under varying environmental conditions further enhances its applicability in these fields.

C. Comparison with Other Types of Resistors

While there are many types of resistors, such as carbon film, metal film, and wire-wound resistors, Resistor 2 stands out due to its specific design and performance characteristics. For instance, metal film resistors are known for their low noise and high stability, while carbon film resistors are often more cost-effective. Resistor 2 may combine the best features of these types, offering a balance of performance and cost that makes it a preferred choice in many applications.

III. Importance of Product Standards

A. Ensuring Safety and Reliability in Electronic Components

Product standards play a crucial role in ensuring the safety and reliability of electronic components. By adhering to established standards, manufacturers can minimize the risk of component failure, which can lead to hazardous situations, especially in critical applications like medical devices and automotive systems.

B. Facilitating Compatibility and Interoperability in Electronic Systems

Standards also facilitate compatibility and interoperability among different electronic components. When components meet the same standards, they can work together seamlessly, reducing the risk of system failures and enhancing overall performance.

C. Enhancing Consumer Confidence and Market Acceptance

Adherence to product standards enhances consumer confidence in electronic products. When consumers know that a product meets recognized standards, they are more likely to trust its quality and reliability, leading to greater market acceptance and success.

IV. Key Product Standards for Resistor 2

A. International Electrotechnical Commission (IEC) Standards

1. Overview of IEC Standards Relevant to Resistors

The International Electrotechnical Commission (IEC) develops international standards for electrical and electronic technologies. These standards cover various aspects of resistors, including performance, safety, and testing methods.

2. Specific IEC Standards Applicable to Resistor 2

For Resistor 2, specific IEC standards may include IEC 60115, which outlines the general requirements for fixed resistors, and IEC 60068, which details environmental testing methods. These standards ensure that Resistor 2 meets the necessary performance and reliability criteria.

B. American National Standards Institute (ANSI) Standards

1. Overview of ANSI Standards for Electronic Components

The American National Standards Institute (ANSI) oversees the development of standards for various industries in the United States, including electronics. ANSI standards help ensure that components meet specific performance and safety criteria.

2. Specific ANSI Standards Applicable to Resistor 2

ANSI standards relevant to Resistor 2 may include ANSI/IEEE C37.90, which covers the testing of electrical relays, and ANSI/IEC 60115-1, which provides general requirements for resistors. Compliance with these standards is essential for manufacturers targeting the North American market.

C. Joint Electron Device Engineering Council (JEDEC) Standards

1. Overview of JEDEC Standards for Semiconductor Devices

JEDEC is an organization that develops standards for the semiconductor industry, including electronic components like resistors. Their standards focus on performance, reliability, and testing methods.

2. Specific JEDEC Standards Applicable to Resistor 2

JEDEC standards relevant to Resistor 2 may include JESD22, which outlines reliability testing methods for electronic components. Adhering to these standards ensures that Resistor 2 can withstand the rigors of its intended applications.

D. Other Relevant Standards

1. ISO (International Organization for Standardization) Standards

ISO standards provide guidelines for quality management systems and product quality. Compliance with ISO 9001, for instance, can enhance the manufacturing processes of Resistor 2, ensuring consistent quality.

2. RoHS (Restriction of Hazardous Substances) Compliance

RoHS compliance is crucial for electronic components, including Resistor 2, as it restricts the use of hazardous substances in electrical and electronic equipment. This compliance is essential for manufacturers aiming to market their products in regions with strict environmental regulations.

3. REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) Compliance

REACH compliance ensures that manufacturers assess and manage the risks associated with chemical substances used in their products. For Resistor 2, this means ensuring that all materials used are safe and environmentally friendly.

V. Testing and Quality Assurance

A. Overview of Testing Methods for Resistor 2

1. Electrical Testing (Resistance, Tolerance, Temperature Coefficient)

Electrical testing is crucial for verifying the performance of Resistor 2. This includes measuring its resistance value, tolerance levels, and temperature coefficient to ensure it meets specified standards.

2. Environmental Testing (Temperature, Humidity, Vibration)

Environmental testing assesses how Resistor 2 performs under various conditions, such as extreme temperatures, humidity, and vibration. This testing is vital for applications where the resistor may be exposed to harsh environments.

B. Quality Assurance Processes in Manufacturing

1. Incoming Material Inspection

Quality assurance begins with the inspection of incoming materials. Ensuring that all materials meet specified standards is critical for the overall quality of Resistor 2.

2. In-Process Quality Control

In-process quality control involves monitoring the manufacturing process to identify and rectify any issues that may arise, ensuring that the final product meets all quality standards.

3. Final Product Testing and Certification

Final product testing and certification are essential steps in the quality assurance process. This ensures that Resistor 2 meets all applicable standards before it is released to the market.

VI. Challenges in Meeting Product Standards

A. Technological Advancements and Their Impact on Standards

As technology evolves, so do the standards that govern electronic components. Manufacturers must continuously adapt to these changes, which can be challenging and resource-intensive.

B. Variability in Manufacturing Processes

Variability in manufacturing processes can lead to inconsistencies in product quality. Ensuring that all products meet the same standards requires rigorous quality control measures.

C. Globalization and the Need for Harmonization of Standards

Globalization has led to a diverse market with varying standards across regions. Harmonizing these standards is essential for manufacturers looking to compete internationally.

VII. Future Trends in Resistor Standards

A. Emerging Technologies and Their Influence on Resistor Design

Emerging technologies, such as IoT and AI, are influencing resistor design and performance requirements. Manufacturers must stay ahead of these trends to meet future demands.

B. The Role of Sustainability in Product Standards

Sustainability is becoming increasingly important in product standards. Manufacturers of Resistor 2 will need to focus on environmentally friendly materials and processes to meet evolving consumer expectations.

C. Anticipated Changes in Regulatory Requirements

As regulations continue to evolve, manufacturers must be prepared for changes that may impact the design and production of Resistor 2. Staying informed about regulatory developments is crucial for compliance.

VIII. Conclusion

In conclusion, product standards for Resistor 2 are essential for ensuring safety, reliability, and compatibility in electronic systems. As technology advances and consumer expectations evolve, adherence to these standards will remain critical for manufacturers. The future of resistor standards will likely be shaped by emerging technologies, sustainability concerns, and changing regulatory requirements. By prioritizing compliance with established standards, manufacturers can enhance the quality and reliability of Resistor 2, ultimately benefiting the entire electronics industry.

IX. References

- International Electrotechnical Commission (IEC) publications

- American National Standards Institute (ANSI) standards

- Joint Electron Device Engineering Council (JEDEC) standards

- ISO (International Organization for Standardization) guidelines

- RoHS and REACH compliance documentation

This blog post provides a comprehensive overview of the product standards for Resistor 2, highlighting its importance, applicable standards, testing methods, challenges, and future trends. By understanding these aspects, manufacturers and consumers alike can appreciate the significance of quality and reliability in electronic components.