What components and modules do aluminum capacitors contain?

What Components and Modules Do Aluminum Capacitors Contain?

I. Introduction

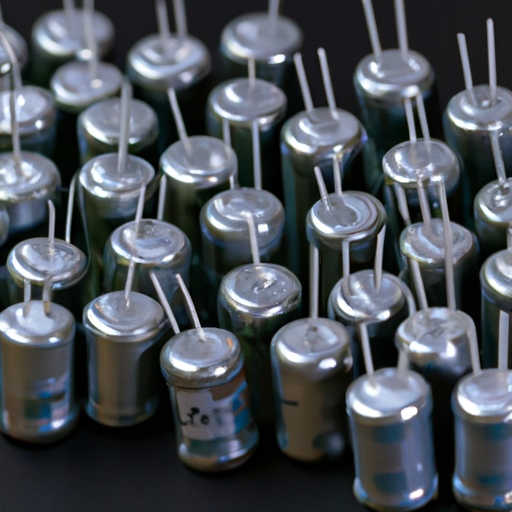

Aluminum capacitors are a vital component in the world of electronics, playing a crucial role in energy storage and management. These capacitors are widely used in various applications, from consumer electronics to industrial machinery, due to their high capacitance values and reliability. In this article, we will explore the components and modules that make up aluminum capacitors, their structure, manufacturing processes, and their significance in modern technology.

II. Basic Structure of Aluminum Capacitors

A. Anode

The anode of an aluminum capacitor is typically made from pure aluminum foil, which serves as the positive electrode. The choice of aluminum is due to its excellent conductivity and lightweight properties. A critical aspect of the anode is the formation of an oxide layer, which acts as the dielectric material. This oxide layer is created through an anodization process, where the aluminum is subjected to an electrolytic solution, resulting in a thin, insulating layer that enhances the capacitor's performance.

B. Cathode

The cathode, or negative electrode, is usually composed of a conductive material, often a liquid or solid electrolyte. The cathode's primary role is to facilitate the flow of electric current and complete the circuit within the capacitor. The interaction between the anode and cathode is essential for the capacitor's functionality, as it allows for the storage and release of electrical energy.

C. Electrolyte

The electrolyte in aluminum capacitors can be either liquid or solid, depending on the type of capacitor. Common electrolytes include aqueous solutions of salts or organic solvents. The electrolyte is crucial for the capacitor's performance, as it not only enhances conductivity but also helps maintain the integrity of the oxide layer. The choice of electrolyte can significantly impact the capacitor's characteristics, such as its capacitance, voltage rating, and temperature stability.

III. Key Components of Aluminum Capacitors

A. Dielectric Layer

The dielectric layer, formed by the anodized oxide on the anode, is a critical component of aluminum capacitors. This layer serves as an insulator, preventing direct current from flowing between the anode and cathode while allowing alternating current to pass. The thickness and quality of the dielectric layer directly influence the capacitor's capacitance and voltage rating. A well-formed dielectric layer is essential for the capacitor's reliability and longevity.

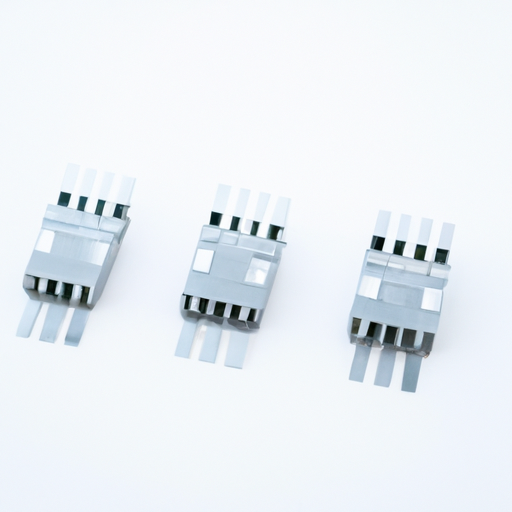

B. Leads and Terminals

Leads and terminals are essential for connecting aluminum capacitors to electronic circuits. The leads are typically made of metal and are attached to the anode and cathode. There are various types of leads, including radial and axial leads, which determine how the capacitor is mounted on a circuit board. Proper connection to the circuitry is vital for ensuring optimal performance and preventing failures.

C. Housing and Encapsulation

The housing of aluminum capacitors is designed to protect the internal components from environmental factors such as moisture, dust, and mechanical stress. Common materials used for housing include aluminum cans and plastic encapsulation. The choice of housing material can affect the capacitor's thermal performance and overall durability. Effective encapsulation is crucial for maintaining the integrity of the capacitor over its operational lifespan.

IV. Modules and Variants of Aluminum Capacitors

A. Standard Aluminum Electrolytic Capacitors

Standard aluminum electrolytic capacitors are the most common type, characterized by their high capacitance values and relatively low cost. They are widely used in power supply circuits, audio equipment, and various consumer electronics. Their ability to store large amounts of energy makes them ideal for applications requiring significant power bursts.

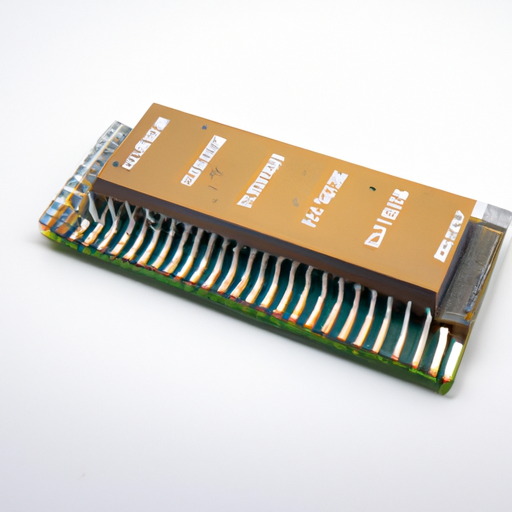

B. SMD (Surface Mount Device) Aluminum Capacitors

SMD aluminum capacitors are designed for surface mounting on printed circuit boards (PCBs). They are smaller and lighter than traditional capacitors, making them suitable for compact electronic devices. SMD capacitors are increasingly popular in modern electronics due to their ease of assembly and space-saving design.

C. Specialty Aluminum Capacitors

Specialty aluminum capacitors include high-temperature and low-equivalent series resistance (ESR) capacitors. High-temperature capacitors are designed to operate in extreme conditions, making them suitable for automotive and industrial applications. Low-ESR capacitors are essential for high-frequency applications, as they minimize energy loss and improve efficiency.

V. Manufacturing Process of Aluminum Capacitors

A. Material Selection

The manufacturing process of aluminum capacitors begins with the careful selection of materials. High-purity aluminum is chosen for the anode, while the electrolyte and cathode materials are selected based on the desired performance characteristics.

B. Anodization Process

The anodization process is critical for forming the dielectric layer on the anode. The aluminum foil is immersed in an electrolytic solution, where an electric current is applied. This process creates a thin, stable oxide layer that enhances the capacitor's performance and reliability.

C. Assembly and Testing

After anodization, the components are assembled, and the capacitor is filled with the chosen electrolyte. The assembly process must be conducted in a controlled environment to prevent contamination. Once assembled, the capacitors undergo rigorous testing to ensure they meet specified performance standards.

D. Quality Control Measures

Quality control is paramount in the manufacturing of aluminum capacitors. Various tests, including capacitance measurement, voltage testing, and temperature cycling, are conducted to ensure the capacitors meet industry standards. Manufacturers implement strict quality control measures to guarantee the reliability and longevity of their products.

VI. Performance Characteristics

A. Capacitance Values

Aluminum capacitors are available in a wide range of capacitance values, typically ranging from microfarads (µF) to farads (F). The capacitance value determines the amount of electrical charge the capacitor can store, making it a critical specification for designers.

B. Voltage Ratings

Voltage ratings indicate the maximum voltage a capacitor can handle without failure. Exceeding this rating can lead to catastrophic failure, making it essential for engineers to select capacitors with appropriate voltage ratings for their applications.

C. Equivalent Series Resistance (ESR)

Equivalent series resistance (ESR) is a measure of the internal resistance of a capacitor. Low ESR is desirable in many applications, as it reduces energy loss and improves efficiency, particularly in high-frequency circuits.

D. Temperature Coefficients

Temperature coefficients indicate how a capacitor's performance changes with temperature. Understanding these coefficients is crucial for ensuring reliable operation in varying environmental conditions.

VII. Applications of Aluminum Capacitors

A. Consumer Electronics

Aluminum capacitors are widely used in consumer electronics, including televisions, smartphones, and audio equipment. Their ability to store and release energy efficiently makes them ideal for power supply circuits and signal processing.

B. Industrial Equipment

In industrial settings, aluminum capacitors are employed in machinery, automation systems, and power distribution. Their robustness and reliability are essential for maintaining operational efficiency in demanding environments.

C. Automotive Applications

The automotive industry relies on aluminum capacitors for various applications, including engine control units, infotainment systems, and electric vehicle power management. Their ability to withstand high temperatures and vibrations makes them suitable for automotive environments.

D. Renewable Energy Systems

Aluminum capacitors play a crucial role in renewable energy systems, such as solar inverters and wind turbine controllers. They help manage energy storage and conversion, contributing to the efficiency of these systems.

VIII. Conclusion

In summary, aluminum capacitors are complex components composed of various materials and modules that work together to store and manage electrical energy. Understanding their structure, components, and performance characteristics is essential for engineers and designers in the electronics industry. As technology continues to evolve, advancements in aluminum capacitor technology will likely lead to improved performance and new applications, making them an indispensable part of modern electronics.

IX. References

- Academic Journals on Capacitor Technology

- Industry Publications on Electronics Components

- Manufacturer Specifications for Aluminum Capacitors

By delving into the components and modules of aluminum capacitors, we gain a deeper appreciation for their role in the electronic devices we rely on every day. Understanding these components not only aids in the design and selection of capacitors but also highlights the importance of quality and reliability in electronic manufacturing.