An article to help you understand what capacitor protection is

An Article to Help You Understand What Capacitor Protection Is

I. Introduction

In the realm of electrical engineering, capacitors play a crucial role in the functionality of various systems. However, like any component, they are susceptible to damage if not adequately protected. This is where capacitor protection comes into play. Capacitor protection refers to the methods and strategies employed to safeguard capacitors from potential risks that could lead to their failure. Understanding capacitor protection is essential for maintaining the reliability and safety of electrical systems. In this article, we will explore the fundamentals of capacitors, the necessity of protection, various protection methods, best practices, real-world case studies, and future trends in capacitor protection.

II. Understanding Capacitors

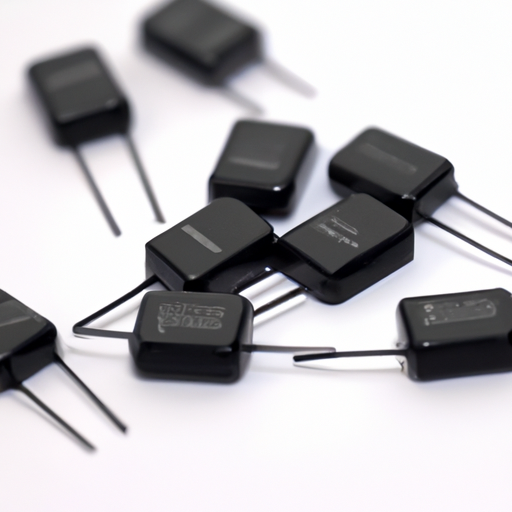

A. What is a Capacitor?

A capacitor is an electronic component that stores electrical energy in an electric field. It consists of two conductive plates separated by an insulating material known as a dielectric. When voltage is applied across the plates, an electric field is created, allowing the capacitor to store energy.

1. Basic Functionality

The primary function of a capacitor is to store and release electrical energy. This ability makes capacitors essential in various applications, including power supply smoothing, energy storage, and timing circuits.

2. Types of Capacitors

There are several types of capacitors, including ceramic, electrolytic, tantalum, and film capacitors. Each type has its unique characteristics, making them suitable for different applications. For instance, electrolytic capacitors are often used in power supply circuits due to their high capacitance values, while ceramic capacitors are favored for high-frequency applications.

B. Role of Capacitors in Electrical Circuits

Capacitors serve multiple functions in electrical circuits:

1. Energy Storage

Capacitors can store energy and release it when needed, making them vital in applications like power supplies and energy storage systems.

2. Filtering and Smoothing

In power supply circuits, capacitors help filter out voltage fluctuations, providing a stable output voltage. They smooth out the ripples in the output of rectifiers, ensuring a consistent power supply.

3. Timing Applications

Capacitors are also used in timing circuits, where they charge and discharge at specific rates to create time delays.

III. The Need for Capacitor Protection

A. Common Risks and Failures

Despite their importance, capacitors are vulnerable to various risks that can lead to failure:

1. Overvoltage Conditions

Exceeding the voltage rating of a capacitor can cause dielectric breakdown, leading to catastrophic failure.

2. Overcurrent Situations

Excessive current can generate heat within the capacitor, potentially causing it to fail or even explode.

3. Environmental Factors (Temperature, Humidity)

Extreme temperatures and humidity can degrade the dielectric material, reducing the capacitor's lifespan and performance.

B. Consequences of Unprotected Capacitors

Failing to protect capacitors can have severe consequences:

1. Equipment Damage

A failed capacitor can lead to damage in other components of the electrical system, resulting in costly repairs.

2. System Downtime

Capacitor failures can cause system outages, leading to significant downtime and loss of productivity.

3. Safety Hazards

In some cases, capacitor failures can pose safety risks, including electrical fires or explosions.

IV. Capacitor Protection Methods

To mitigate the risks associated with capacitors, various protection methods can be employed:

A. Fuses and Circuit Breakers

1. Functionality and Types

Fuses and circuit breakers are designed to interrupt the flow of current when it exceeds a certain threshold. Fuses are one-time use devices, while circuit breakers can be reset after tripping.

2. Advantages and Limitations

While fuses and circuit breakers provide essential protection, they may not respond quickly enough to transient events, such as voltage spikes.

B. Surge Protection Devices (SPDs)

1. How SPDs Work

Surge protection devices are designed to protect electrical equipment from voltage spikes by diverting excess voltage away from sensitive components.

2. Types of SPDs

There are various types of SPDs, including metal-oxide varistors (MOVs) and gas discharge tubes (GDTs), each with its unique characteristics and applications.

C. Thermal Protection

1. Temperature Sensors and Cutoffs

Thermal protection involves using temperature sensors to monitor the operating temperature of capacitors. If the temperature exceeds a predetermined threshold, the system can automatically disconnect the capacitor.

2. Benefits of Thermal Protection

This method helps prevent overheating and extends the lifespan of capacitors by ensuring they operate within safe temperature limits.

D. Voltage Regulation

1. Voltage Regulators and Their Role

Voltage regulators maintain a consistent output voltage, protecting capacitors from overvoltage conditions.

2. Importance of Maintaining Voltage Levels

Maintaining stable voltage levels is crucial for the reliable operation of electrical systems and the longevity of capacitors.

E. Capacitor Monitoring Systems

1. Real-time Monitoring Technologies

Advanced monitoring systems can provide real-time data on capacitor performance, allowing for proactive maintenance and early detection of potential issues.

2. Predictive Maintenance and Alerts

By analyzing data trends, these systems can predict when a capacitor is likely to fail, enabling timely intervention and reducing the risk of unexpected failures.

V. Best Practices for Capacitor Protection

To ensure the longevity and reliability of capacitors, several best practices should be followed:

A. Regular Maintenance and Inspection

Routine inspections can help identify potential issues before they lead to failures. Regular maintenance ensures that capacitors are functioning optimally.

B. Proper Sizing and Selection of Capacitors

Choosing the right capacitor for the application is critical. Factors such as voltage rating, capacitance value, and environmental conditions should be considered during selection.

C. Environmental Considerations

Capacitors should be installed in environments that minimize exposure to extreme temperatures and humidity. Proper housing and ventilation can help protect capacitors from environmental stressors.

D. Training and Awareness for Personnel

Educating personnel about the importance of capacitor protection and best practices can help prevent mishandling and ensure that protective measures are implemented effectively.

VI. Case Studies

A. Examples of Capacitor Failures and Their Impact

Several industries have experienced significant losses due to capacitor failures. For instance, in the manufacturing sector, a failed capacitor in a critical machine led to a production halt, resulting in substantial financial losses.

B. Successful Implementation of Protection Strategies

Conversely, companies that have implemented robust capacitor protection strategies have seen improved reliability and reduced downtime. For example, a power plant that adopted real-time monitoring systems for its capacitors reported a 30% decrease in unexpected failures.

C. Lessons Learned from Real-world Scenarios

These case studies highlight the importance of proactive capacitor protection measures and the potential consequences of neglecting them.

VII. Future Trends in Capacitor Protection

A. Advances in Technology

As technology continues to evolve, new materials and designs for capacitors are being developed, enhancing their performance and reliability.

B. Integration with Smart Grid Systems

The integration of capacitors with smart grid technology allows for better monitoring and management of electrical systems, improving overall efficiency.

C. The Role of Artificial Intelligence in Predictive Maintenance

Artificial intelligence is increasingly being used to analyze data from capacitor monitoring systems, enabling predictive maintenance and reducing the likelihood of unexpected failures.

VIII. Conclusion

In conclusion, capacitor protection is a vital aspect of maintaining the reliability and safety of electrical systems. By understanding the risks associated with unprotected capacitors and implementing effective protection strategies, organizations can prevent equipment damage, minimize downtime, and ensure the safety of personnel. As technology continues to advance, the future of capacitor protection looks promising, with new methods and tools emerging to enhance the resilience of electrical systems. It is crucial for industries to prioritize capacitor protection and invest in the necessary measures to safeguard their operations.

IX. References

A. Suggested Reading and Resources

1. "Capacitor Technology and Applications" - A comprehensive guide on capacitors and their uses.

2. "Electrical Protection Systems" - A resource on various protection methods for electrical components.

B. Industry Standards and Guidelines

1. IEEE Standards for Capacitor Protection

2. National Electrical Code (NEC) Guidelines for Capacitor Installation and Protection

By following the insights and recommendations outlined in this article, readers can gain a deeper understanding of capacitor protection and its significance in electrical systems.