What are the latest washing machine capacitors and equipment components procurement models?

What are the Latest Washing Machine Capacitors and Equipment Components Procurement Models?

I. Introduction

Washing machines are essential appliances in modern households, and their efficient operation relies heavily on various components, particularly capacitors. These small yet crucial devices play a significant role in the functionality of washing machines, affecting everything from motor operation to energy efficiency. As the demand for high-performance washing machines continues to rise, so does the importance of effective procurement models for the components that make them work. This article explores the latest trends in washing machine capacitors and procurement models, shedding light on how manufacturers and repair businesses can adapt to the evolving landscape.

II. Understanding Washing Machine Capacitors

A. Definition and Function of Capacitors in Washing Machines

Capacitors are electrical components that store and release energy, playing a vital role in the operation of washing machine motors. They help start the motor by providing an initial boost of energy, which is crucial for getting the machine running. Additionally, capacitors contribute to the overall energy efficiency of washing machines by ensuring that motors operate smoothly and effectively.

B. Types of Capacitors Used in Washing Machines

1. **Start Capacitors**: These capacitors provide the necessary energy to start the motor. They are typically used in single-phase motors and are designed to disconnect from the circuit once the motor reaches a certain speed.

2. **Run Capacitors**: Unlike start capacitors, run capacitors remain in the circuit during the motor's operation. They help improve the motor's efficiency and performance by providing a continuous supply of energy.

3. **Dual Capacitors**: These capacitors combine the functions of both start and run capacitors in a single unit, making them versatile and efficient for various washing machine applications.

C. Recent Advancements in Capacitor Technology

Recent advancements in capacitor technology have led to improved materials and designs that enhance durability and performance. Manufacturers are now using higher-quality dielectric materials that can withstand greater temperatures and voltages, resulting in longer-lasting capacitors. Additionally, advancements in manufacturing processes have allowed for more compact designs, making it easier to integrate capacitors into modern washing machines.

III. The Importance of Equipment Components in Washing Machines

A. Overview of Key Components in Washing Machines

Washing machines consist of several key components, including:

1. **Motors**: The heart of the washing machine, responsible for driving the drum and facilitating the washing process.

2. **Control Boards**: These electronic components manage the various functions of the washing machine, including cycle selection, water levels, and motor speed.

3. **Pumps and Valves**: Essential for water intake and drainage, these components ensure that the washing machine operates efficiently.

B. The Role of Capacitors in the Overall Performance of These Components

Capacitors are integral to the performance of motors and control boards. They help regulate voltage and current, ensuring that motors operate smoothly and efficiently. A malfunctioning capacitor can lead to poor motor performance, increased energy consumption, and ultimately, a shorter lifespan for the washing machine.

C. Trends in Component Design and Manufacturing

The trend towards energy-efficient appliances has led to innovations in component design and manufacturing. Manufacturers are focusing on creating components that not only perform better but also consume less energy. This shift is driven by consumer demand for sustainable products and regulatory pressures to reduce energy consumption.

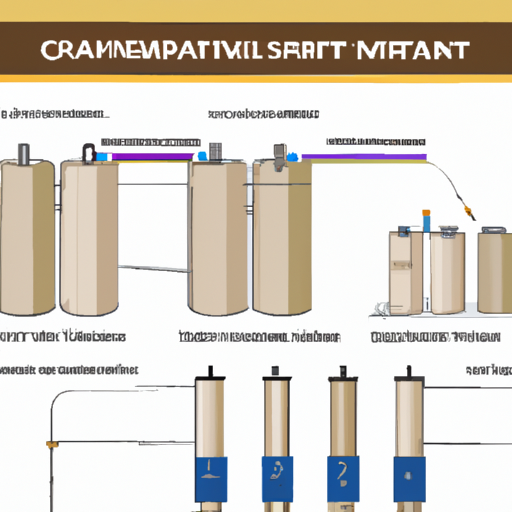

IV. Procurement Models for Washing Machine Components

A. Traditional Procurement Models

1. **Direct Purchasing from Manufacturers**: Many manufacturers opt to purchase components directly from producers, ensuring quality control and potentially lower costs.

2. **Distributors and Wholesalers**: This traditional model allows manufacturers to source components from various suppliers, providing flexibility and a broader range of options.

B. Emerging Procurement Models

1. **Just-in-Time (JIT) Procurement**: This model minimizes inventory costs by ordering components only as they are needed. JIT procurement can lead to significant cost savings and reduced waste.

2. **E-Procurement Platforms**: The rise of digital platforms has transformed procurement processes, allowing manufacturers to source components online, compare prices, and streamline purchasing.

3. **Collaborative Procurement**: This model involves multiple companies working together to procure components, leveraging collective buying power to negotiate better prices and terms.

C. The Role of Technology in Modern Procurement

Technology plays a crucial role in modern procurement, with supply chain management software and data analytics becoming essential tools. These technologies enable manufacturers to forecast demand accurately, manage inventory levels, and optimize their procurement strategies.

V. Factors Influencing Procurement Decisions

Several factors influence procurement decisions for washing machine components:

A. Cost Considerations

Cost remains a primary factor in procurement decisions. Manufacturers must balance the need for high-quality components with budget constraints, often leading to negotiations with suppliers.

B. Quality and Reliability of Components

The quality and reliability of components are critical for ensuring the performance and longevity of washing machines. Manufacturers often prioritize suppliers with a proven track record of delivering high-quality products.

C. Supplier Relationships and Partnerships

Building strong relationships with suppliers can lead to better pricing, improved service, and access to the latest technologies. Manufacturers often seek long-term partnerships to enhance their procurement processes.

D. Sustainability and Environmental Impact

As consumers become more environmentally conscious, manufacturers are increasingly considering the sustainability of their procurement practices. This includes sourcing components from suppliers that prioritize eco-friendly materials and processes.

E. Regulatory Compliance and Standards

Compliance with industry regulations and standards is essential for manufacturers. Procurement decisions must consider the certifications and quality standards required for components used in washing machines.

VI. Case Studies of Successful Procurement Models

A. Example 1: A Leading Washing Machine Manufacturer

One leading washing machine manufacturer adopted a JIT procurement model, significantly reducing inventory costs and improving cash flow. By collaborating closely with suppliers, they were able to streamline their supply chain and enhance component quality, resulting in a more efficient production process.

B. Example 2: A Small Appliance Repair Business

A small appliance repair business implemented an e-procurement platform to source components more efficiently. This innovative approach allowed them to access a wider range of suppliers, reducing lead times and improving customer satisfaction through faster service delivery.

VII. Challenges in Procurement of Washing Machine Components

Despite advancements in procurement models, several challenges persist:

A. Supply Chain Disruptions

Global events, such as pandemics and geopolitical tensions, can disrupt supply chains, leading to delays and increased costs for manufacturers.

B. Fluctuating Material Costs

The cost of raw materials can fluctuate significantly, impacting procurement budgets and forcing manufacturers to adapt their strategies.

C. Quality Control Issues

Ensuring consistent quality across suppliers can be challenging, particularly when sourcing components from multiple sources.

D. Adapting to Technological Changes

As technology evolves, manufacturers must stay abreast of new developments in component design and procurement practices to remain competitive.

VIII. Future Trends in Washing Machine Capacitors and Procurement Models

A. Predictions for Capacitor Technology Advancements

The future of capacitor technology is likely to see further advancements in materials and designs, leading to even more efficient and durable components. Innovations such as smart capacitors that can monitor performance and provide real-time data may become commonplace.

B. The Evolution of Procurement Models in the Appliance Industry

Procurement models will continue to evolve, with a greater emphasis on digital solutions and collaborative approaches. Manufacturers will increasingly leverage technology to enhance their procurement processes and improve supply chain resilience.

C. The Impact of Global Market Trends on Procurement Strategies

Global market trends, including shifts towards sustainability and digitalization, will shape procurement strategies in the washing machine industry. Manufacturers will need to adapt to these changes to remain competitive and meet consumer demands.

IX. Conclusion

In conclusion, capacitors play a vital role in the performance of washing machines, and understanding the latest trends in procurement models is essential for manufacturers and repair businesses. As the industry evolves, embracing innovative procurement strategies and advancements in capacitor technology will be crucial for success. Manufacturers and suppliers must remain agile and responsive to changing trends to ensure they meet the demands of the modern market.

X. References

A comprehensive list of academic articles, industry reports, and other resources used in this article would be included here to provide readers with further reading and validation of the information presented.

---

This blog post provides a detailed exploration of the latest trends in washing machine capacitors and procurement models, offering insights for manufacturers and repair businesses looking to adapt to the evolving landscape.