What are the advantages of capacitor specification products?

What are the Advantages of Capacitor Specification Products?

I. Introduction

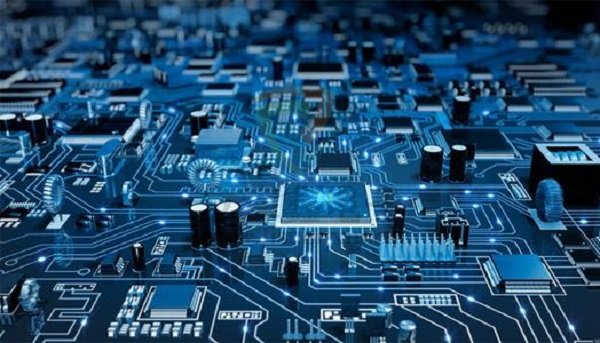

In the world of electronics, capacitors play a crucial role in the functionality and performance of various devices. Capacitor specification products refer to capacitors that are designed and manufactured according to specific parameters and standards, ensuring they meet the unique requirements of different applications. Understanding the importance of capacitor specifications is essential for engineers, designers, and manufacturers alike, as it directly impacts the performance, reliability, and longevity of electronic systems. This article aims to explore the advantages of capacitor specification products, highlighting their significance in various industries.

II. Understanding Capacitors

A. Basic Functionality of Capacitors

Capacitors are passive electronic components that store and release electrical energy. They consist of two conductive plates separated by an insulating material known as a dielectric. When voltage is applied, an electric field is created, allowing the capacitor to store energy. This stored energy can be released when needed, making capacitors essential for smoothing out voltage fluctuations, filtering signals, and providing power in various applications.

B. Types of Capacitors

There are several types of capacitors, each with unique characteristics and applications:

1. **Ceramic Capacitors**: Known for their small size and high stability, ceramic capacitors are widely used in high-frequency applications.

2. **Electrolytic Capacitors**: These capacitors offer high capacitance values and are commonly used in power supply circuits.

3. **Film Capacitors**: With excellent stability and low losses, film capacitors are often used in audio and high-frequency applications.

4. **Tantalum Capacitors**: Known for their reliability and compact size, tantalum capacitors are used in applications where space is limited.

C. Applications of Capacitors in Various Industries

Capacitors are utilized across a wide range of industries, including consumer electronics, automotive, telecommunications, renewable energy, and industrial automation. Their versatility makes them indispensable in modern electronic systems.

III. Importance of Capacitor Specifications

A. Role of Specifications in Performance

Capacitor specifications define the electrical characteristics, physical dimensions, and environmental tolerances of a capacitor. These specifications are critical in determining how well a capacitor will perform in a given application. For instance, the capacitance value, voltage rating, and temperature coefficient are essential parameters that influence a capacitor's behavior in a circuit.

B. Impact on Reliability and Longevity

Proper specifications ensure that capacitors can withstand the operating conditions they will encounter. This includes factors such as temperature fluctuations, humidity, and voltage spikes. Capacitors that meet stringent specifications are less likely to fail, leading to increased reliability and longevity of the overall system.

C. Compliance with Industry Standards

Adhering to industry standards is vital for ensuring safety and performance. Capacitor specification products are often designed to meet specific regulatory requirements, which can vary by industry. Compliance with these standards not only enhances product quality but also builds trust with consumers and clients.

IV. Advantages of Capacitor Specification Products

A. Enhanced Performance

1. Improved Efficiency

Capacitor specification products are engineered to optimize performance in specific applications. By selecting capacitors with the right specifications, designers can achieve improved efficiency in energy storage and signal processing, leading to better overall system performance.

2. Better Frequency Response

Different applications require capacitors to perform effectively across various frequency ranges. Specification products are designed to provide optimal frequency response, ensuring that they can handle the demands of high-frequency signals without distortion or loss of performance.

B. Increased Reliability

1. Reduced Failure Rates

Capacitors that are manufactured according to strict specifications are less prone to failure. This is particularly important in critical applications, such as medical devices and aerospace systems, where reliability is paramount.

2. Extended Lifespan

By using capacitors that meet the necessary specifications, manufacturers can extend the lifespan of their products. This not only reduces the need for replacements but also minimizes downtime and maintenance costs.

C. Customization and Flexibility

1. Tailored Solutions for Specific Applications

Capacitor specification products can be customized to meet the unique needs of different applications. This flexibility allows engineers to select capacitors that are perfectly suited for their designs, enhancing overall system performance.

2. Variety of Options for Different Needs

With a wide range of capacitor types and specifications available, designers have the freedom to choose from various options. This variety ensures that they can find the right capacitor for any application, whether it requires high capacitance, low ESR, or specific temperature ratings.

D. Cost-Effectiveness

1. Long-Term Savings

While capacitor specification products may have a higher upfront cost, their enhanced performance and reliability can lead to significant long-term savings. Fewer failures and replacements translate to lower overall costs for manufacturers and consumers alike.

2. Reduced Maintenance Costs

Capacitors that are designed to meet specific specifications require less maintenance and are less likely to fail. This reduction in maintenance needs can lead to substantial cost savings over the lifespan of a product.

E. Simplified Design Process

1. Streamlined Selection Process

Having access to capacitor specification products simplifies the selection process for engineers. With clear specifications and performance data, designers can quickly identify the right capacitors for their applications, saving time and effort.

2. Compatibility with Existing Systems

Capacitor specification products are often designed with compatibility in mind. This ensures that they can be easily integrated into existing systems, reducing the need for extensive redesigns and modifications.

V. Case Studies and Real-World Applications

A. Consumer Electronics

In consumer electronics, capacitor specification products are essential for ensuring high-quality audio and video performance. For example, film capacitors are commonly used in audio equipment to provide clear sound without distortion.

B. Automotive Industry

The automotive industry relies heavily on capacitors for various applications, including power management and signal processing. Tantalum capacitors, known for their reliability, are often used in critical automotive systems, such as engine control units.

C. Renewable Energy Systems

In renewable energy systems, such as solar inverters, capacitors play a vital role in energy storage and conversion. Specification products designed for high voltage and temperature stability are crucial for ensuring the efficiency and longevity of these systems.

D. Industrial Automation

Capacitors are widely used in industrial automation for motor control and power factor correction. Specification products that meet the demands of harsh environments are essential for maintaining system reliability and performance.

VI. Challenges and Considerations

A. Understanding Specifications

One of the challenges in selecting capacitor specification products is understanding the various specifications and how they impact performance. Engineers must be well-versed in capacitor characteristics to make informed decisions.

B. Balancing Cost and Quality

While high-quality capacitors may come at a premium, it is essential to balance cost with performance and reliability. Investing in specification products can lead to long-term savings, but careful consideration is necessary to avoid overspending.

C. Keeping Up with Technological Advancements

The field of electronics is constantly evolving, and new capacitor technologies are regularly introduced. Staying informed about the latest advancements and trends is crucial for engineers and manufacturers to ensure they are using the best components available.

VII. Conclusion

In summary, capacitor specification products offer numerous advantages that enhance the performance, reliability, and longevity of electronic systems. By understanding the importance of specifications and selecting the right capacitors for specific applications, engineers can optimize their designs and achieve better results. As technology continues to advance, the role of capacitor specifications will remain critical in ensuring the success of electronic devices across various industries. Proper specifications not only improve product quality but also contribute to cost savings and customer satisfaction, making them an essential consideration in the design and manufacturing process.

VIII. References

- Academic Journals

- Industry Reports

- Manufacturer Specifications and Guidelines

In conclusion, the advantages of capacitor specification products are clear. They provide enhanced performance, increased reliability, customization options, cost-effectiveness, and a simplified design process. As the demand for high-quality electronic components continues to grow, understanding and utilizing capacitor specifications will be vital for success in the ever-evolving world of electronics.