Mainstream aluminum electrolytic capacitor product series parameters

Mainstream Aluminum Electrolytic Capacitor Product Series Parameters

I. Introduction

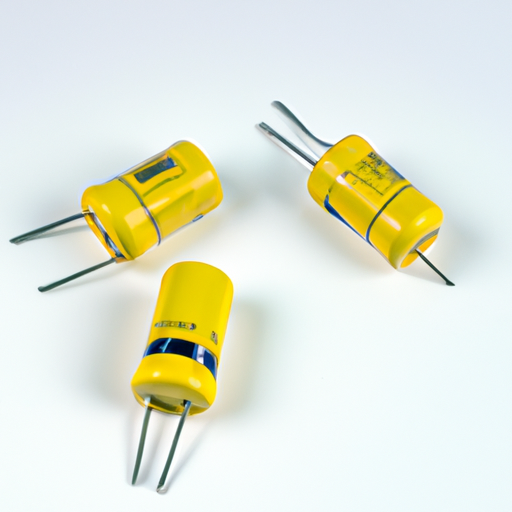

Aluminum electrolytic capacitors are essential components in modern electronic circuits, playing a critical role in energy storage, filtering, and signal coupling. These capacitors are widely used due to their high capacitance values and relatively low cost, making them a popular choice in various applications, from consumer electronics to industrial machinery. This blog post aims to provide a comprehensive overview of the parameters associated with mainstream aluminum electrolytic capacitor product series, helping engineers and designers make informed decisions when selecting these components for their projects.

II. Basics of Aluminum Electrolytic Capacitors

A. Construction and Components

Aluminum electrolytic capacitors consist of several key components:

1. **Anode and Cathode**: The anode is typically made of aluminum foil, which is oxidized to form a thin dielectric layer. The cathode is usually a liquid or solid electrolyte that facilitates the flow of electric current.

2. **Electrolyte**: The electrolyte serves as the conductive medium between the anode and cathode, allowing for the storage and release of electrical energy.

3. **Dielectric Layer**: The dielectric layer, formed during the anodization of the aluminum foil, is crucial for the capacitor's ability to store charge. Its thickness and quality directly influence the capacitor's performance.

B. Working Principle

The working principle of aluminum electrolytic capacitors is based on the storage of electrical energy in an electric field created between the anode and cathode. When a voltage is applied, positive and negative charges accumulate on the anode and cathode, respectively, creating a potential difference. The capacitor can then release this stored energy when needed.

C. Types of Aluminum Electrolytic Capacitors

There are several types of aluminum electrolytic capacitors, each designed for specific applications:

1. **Standard Capacitors**: These are the most common type, suitable for general-purpose applications.

2. **Low-ESR Capacitors**: Designed for high-frequency applications, low equivalent series resistance (ESR) capacitors minimize energy loss and improve efficiency.

3. **High-Temperature Capacitors**: These capacitors can operate in elevated temperature environments, making them ideal for automotive and industrial applications.

III. Key Parameters of Aluminum Electrolytic Capacitors

Understanding the key parameters of aluminum electrolytic capacitors is essential for selecting the right component for a specific application.

A. Capacitance Value

1. **Measurement Units**: Capacitance is measured in farads (F), with microfarads (µF) being the most common unit used in practical applications.

2. **Tolerance Levels**: Capacitors come with specified tolerance levels, indicating how much the actual capacitance can vary from the stated value. Common tolerances range from ±5% to ±20%.

B. Voltage Rating

1. **Definition and Importance**: The voltage rating indicates the maximum voltage the capacitor can withstand without failure. Exceeding this rating can lead to catastrophic failure.

2. **Derating Guidelines**: It is advisable to operate capacitors at a voltage significantly lower than their rated voltage (typically 70-80%) to enhance reliability and lifespan.

C. Equivalent Series Resistance (ESR)

1. **Definition and Impact on Performance**: ESR is the internal resistance of the capacitor, affecting its efficiency and heat generation. Lower ESR values are desirable for high-frequency applications.

2. **Measurement Techniques**: ESR can be measured using specialized equipment, such as an LCR meter, which applies a small AC signal to determine the resistance.

D. Ripple Current Rating

1. **Definition and Importance**: Ripple current rating indicates the maximum AC current the capacitor can handle without overheating. Exceeding this rating can lead to reduced lifespan and performance.

2. **Effects on Lifespan and Performance**: High ripple currents can cause increased heat generation, leading to dielectric breakdown and reduced reliability.

E. Temperature Range

1. **Operating Temperature Limits**: Aluminum electrolytic capacitors have specified operating temperature ranges, typically from -40°C to +105°C, depending on the design.

2. **Impact on Performance and Reliability**: Operating outside the specified temperature range can lead to reduced capacitance, increased ESR, and shortened lifespan.

F. Lifetime and Reliability

1. **Factors Affecting Lifespan**: The lifespan of aluminum electrolytic capacitors is influenced by factors such as temperature, voltage, and ripple current.

2. **Failure Mechanisms**: Common failure mechanisms include electrolyte evaporation, dielectric breakdown, and corrosion of the anode.

IV. Mainstream Product Series Overview

A. Popular Manufacturers

Several manufacturers dominate the aluminum electrolytic capacitor market, each offering a range of products tailored to different applications.

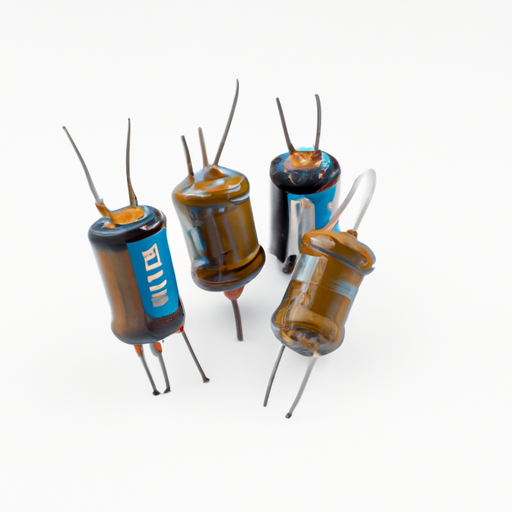

1. **Overview of Leading Brands**: Companies like Nichicon, Panasonic, and Rubycon are well-known for their high-quality capacitors, each with unique product lines.

2. **Comparison of Product Offerings**: While all manufacturers provide standard capacitors, some specialize in low-ESR or high-temperature variants, catering to specific market needs.

B. Product Series Examples

1. **Series A: Specifications and Applications**: Series A capacitors from Manufacturer X are designed for general-purpose applications, featuring a capacitance range of 1µF to 1000µF and a voltage rating of up to 50V.

2. **Series B: Specifications and Applications**: Series B capacitors from Manufacturer Y focus on low-ESR applications, suitable for power supply circuits, with ESR values as low as 10mΩ.

3. **Series C: Specifications and Applications**: Series C capacitors from Manufacturer Z are high-temperature rated, capable of operating at temperatures up to 125°C, making them ideal for automotive applications.

V. Applications of Aluminum Electrolytic Capacitors

Aluminum electrolytic capacitors find applications across various industries:

A. Consumer Electronics

In consumer electronics, these capacitors are used in power supplies, audio equipment, and signal processing circuits, where their high capacitance values are essential for performance.

B. Industrial Equipment

In industrial settings, aluminum electrolytic capacitors are employed in motor drives, power inverters, and control systems, where reliability and efficiency are critical.

C. Automotive Applications

Automotive electronics utilize these capacitors for power management, infotainment systems, and safety features, requiring components that can withstand harsh environments.

D. Renewable Energy Systems

In renewable energy systems, such as solar inverters and wind turbines, aluminum electrolytic capacitors play a vital role in energy storage and conversion, ensuring efficient operation.

VI. Selection Criteria for Aluminum Electrolytic Capacitors

When selecting aluminum electrolytic capacitors, several criteria should be considered:

A. Application Requirements

Understanding the specific requirements of the application, including voltage, capacitance, and temperature, is crucial for selecting the right capacitor.

B. Environmental Considerations

Factors such as humidity, temperature fluctuations, and exposure to chemicals can impact capacitor performance and lifespan.

C. Cost vs. Performance Trade-offs

Balancing cost and performance is essential, as higher-quality capacitors may offer better reliability but at a higher price point.

D. Future Trends in Capacitor Technology

Emerging trends, such as the development of hybrid capacitors and advancements in materials, may influence future capacitor selection and design.

VII. Conclusion

In summary, aluminum electrolytic capacitors are vital components in a wide range of electronic applications. Understanding their key parameters—such as capacitance value, voltage rating, ESR, ripple current rating, temperature range, and reliability—enables engineers and designers to make informed decisions when selecting these components. As technology continues to evolve, staying abreast of trends and advancements in capacitor technology will be essential for optimizing performance and reliability in electronic circuits.

VIII. References

A comprehensive list of references, including academic journals, industry standards, and manufacturer specifications, can provide further insights into aluminum electrolytic capacitors and their applications.