What are the advantages of film capacitor products?

What are the Advantages of Film Capacitor Products?

I. Introduction

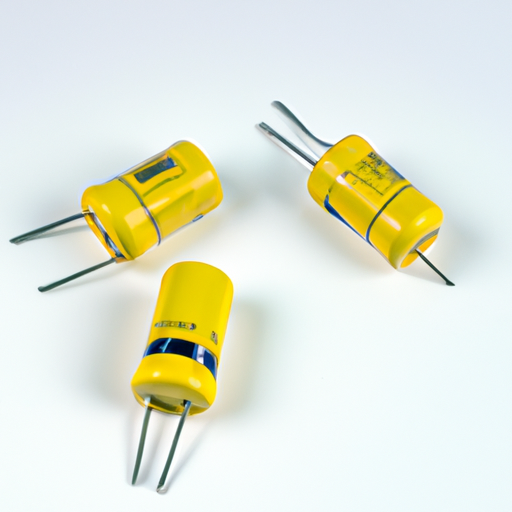

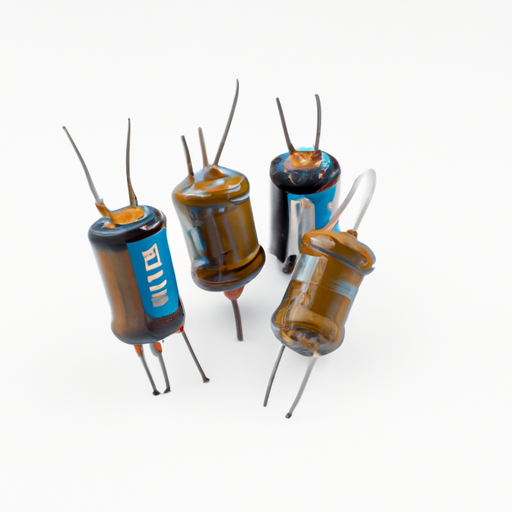

Capacitors are essential components in electronic circuits, serving as energy storage devices that can release energy when needed. Among the various types of capacitors available, film capacitors have gained significant popularity due to their unique properties and advantages. Film capacitors are made from thin plastic films as the dielectric material, which contributes to their performance characteristics. This blog post will explore the advantages of film capacitor products, highlighting their types, key benefits, applications, and comparisons with other capacitor types.

II. Types of Film Capacitors

Film capacitors come in several varieties, each with distinct properties suited for specific applications:

A. Polyester Capacitors

Polyester capacitors, also known as Mylar capacitors, are widely used due to their affordability and decent performance. They are suitable for general-purpose applications, including coupling and decoupling.

B. Polypropylene Capacitors

Polypropylene capacitors are known for their excellent electrical properties, including low dielectric losses and high insulation resistance. They are often used in audio applications and high-frequency circuits.

C. Polycarbonate Capacitors

Polycarbonate capacitors offer good thermal stability and are less sensitive to temperature variations. They are suitable for applications requiring high reliability.

D. Other Types

Other film capacitors include polystyrene and fluorinated polymers, each with unique characteristics that make them suitable for specialized applications.

III. Key Advantages of Film Capacitors

Film capacitors offer several advantages that make them a preferred choice in many electronic applications:

A. High Voltage and Current Ratings

Film capacitors can handle high voltage and current levels, making them suitable for demanding applications. Their ability to withstand high voltages without breakdown is superior to many other capacitor types, such as electrolytic capacitors, which are often limited in voltage ratings.

B. Low Equivalent Series Resistance (ESR)

Equivalent Series Resistance (ESR) is a critical parameter that affects the performance of capacitors. Film capacitors typically exhibit low ESR, which translates to higher efficiency and better performance in high-frequency applications. This characteristic minimizes energy losses and heat generation, making them ideal for power electronics.

C. Excellent Thermal Stability

Film capacitors maintain their performance across a wide temperature range. Their temperature coefficients are favorable, allowing them to operate effectively in high-temperature environments. This thermal stability is crucial for applications in automotive and industrial sectors, where temperature fluctuations are common.

D. Long Lifespan and Reliability

One of the standout features of film capacitors is their long lifespan. Unlike electrolytic capacitors, which can degrade over time due to electrolyte evaporation, film capacitors exhibit excellent aging characteristics. They can last for decades, making them a reliable choice for critical applications.

E. Low Self-Discharge Rate

Film capacitors have a low self-discharge rate, meaning they can retain their charge for extended periods. This property is particularly beneficial in energy storage applications, where maintaining charge over time is essential.

F. Non-Polarized Nature

Film capacitors are non-polarized, allowing them to be connected in either direction in a circuit. This flexibility simplifies circuit design and reduces the risk of installation errors, making them user-friendly.

G. High Insulation Resistance

High insulation resistance is vital for preventing leakage currents in sensitive electronic devices. Film capacitors excel in this area, ensuring that they can be used in applications where insulation integrity is paramount, such as in medical devices and precision instruments.

H. Environmental Resistance

Film capacitors are resistant to moisture, chemicals, and other environmental factors. This durability makes them suitable for harsh environments, such as outdoor applications and industrial settings, where reliability is critical.

IV. Applications of Film Capacitors

Film capacitors find applications across various industries due to their advantageous properties:

A. Audio Equipment

In audio applications, film capacitors play a crucial role in signal processing. Their low distortion and high-frequency response contribute to improved sound quality, making them a preferred choice in high-fidelity audio systems.

B. Power Electronics

Film capacitors are widely used in power electronics, including inverters and converters. Their ability to handle high voltages and currents makes them essential components in renewable energy systems, such as solar inverters and wind turbine controllers.

C. Industrial Equipment

In industrial settings, film capacitors are used in motor drives and control systems. Their reliability and performance in demanding conditions ensure that machinery operates efficiently and safely.

D. Consumer Electronics

Film capacitors are also found in consumer electronics, including televisions, computers, and appliances. Their impact on performance and longevity makes them a valuable component in everyday devices.

V. Comparison with Other Capacitor Types

When selecting capacitors for specific applications, it is essential to compare film capacitors with other types:

A. Electrolytic Capacitors

Electrolytic capacitors are known for their high capacitance values but have limitations in voltage ratings and lifespan. Film capacitors are often preferred in applications requiring reliability and stability over time.

B. Ceramic Capacitors

Ceramic capacitors are popular for their small size and high capacitance, but they can exhibit voltage dependence and temperature sensitivity. Film capacitors, with their superior thermal stability and low ESR, are often chosen for high-frequency applications.

C. Tantalum Capacitors

Tantalum capacitors offer high capacitance in a small package but can be expensive and less reliable under certain conditions. Film capacitors provide a more cost-effective and reliable alternative for many applications.

VI. Conclusion

In summary, film capacitors offer numerous advantages that make them a preferred choice in various electronic applications. Their high voltage and current ratings, low ESR, excellent thermal stability, long lifespan, and environmental resistance are just a few of the reasons why they are widely used in industries ranging from audio equipment to power electronics. As technology continues to evolve, film capacitor technology is expected to advance, further enhancing their performance and expanding their applications. Selecting the right capacitor for specific needs is crucial, and understanding the advantages of film capacitors can help engineers and designers make informed decisions.

VII. References

1. Academic papers and articles on film capacitors.

2. Industry standards and guidelines.

3. Manufacturer specifications and datasheets.

By understanding the advantages of film capacitors, engineers and designers can leverage their unique properties to create more efficient, reliable, and high-performing electronic systems.