What are the 10 most popular models for recycling of mainstream capacitors?

What are the 10 Most Popular Models for Recycling of Mainstream Capacitors?

Introduction

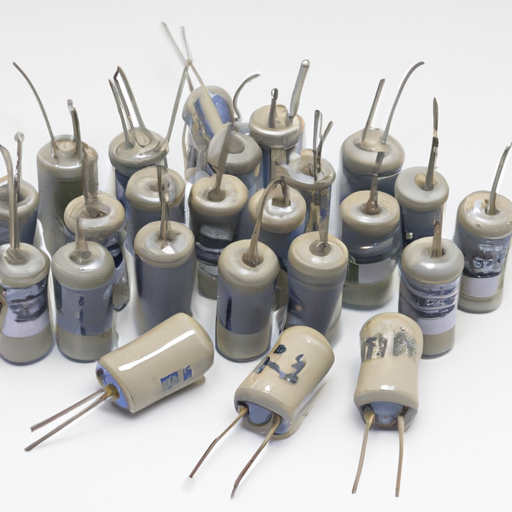

Capacitors are essential components in electronic circuits, playing a crucial role in energy storage, filtering, and signal processing. They are found in a wide range of devices, from smartphones to industrial machinery. However, the increasing use of capacitors has raised concerns about their environmental impact, particularly when it comes to disposal. Improper disposal can lead to hazardous materials leaching into the environment, making recycling a vital process for sustainability and resource recovery. This article explores the ten most popular models for recycling mainstream capacitors, highlighting their processes, benefits, and challenges.

1. Understanding Capacitors

Capacitors are passive electronic components that store and release electrical energy. They consist of two conductive plates separated by an insulating material, known as a dielectric. Common types of capacitors include electrolytic, ceramic, and film capacitors, each with unique properties and applications. The materials used in capacitors vary, with aluminum and tantalum being prevalent in electrolytic capacitors, while ceramic capacitors often use a mix of metal oxides.

2. The Need for Recycling Capacitors

The environmental impact of improper disposal of capacitors cannot be overstated. Many capacitors contain hazardous materials, such as electrolytes and heavy metals, which can contaminate soil and water. Recycling capacitors not only mitigates these risks but also allows for the recovery of valuable materials, such as aluminum, tantalum, and plastics. Regulatory frameworks, such as the Waste Electrical and Electronic Equipment (WEEE) Directive in Europe, promote the recycling of electronic waste, including capacitors, to ensure responsible disposal and resource recovery.

3. Overview of Recycling Processes

Recycling capacitors involves several steps, including collection, sorting, dismantling, and processing. Safety and environmental considerations are paramount throughout the recycling process. Facilities must adhere to strict regulations to minimize the release of hazardous substances and ensure the safe handling of materials.

4. Model 1: Mechanical Separation

Mechanical separation is one of the most straightforward methods for recycling capacitors. This technique involves shredding or crushing capacitors to separate their components. The process typically includes the following steps:

1. **Shredding**: Capacitors are fed into a shredder, which breaks them down into smaller pieces.

2. **Screening**: The shredded material is screened to separate different sizes and types of materials.

3. **Magnetic Separation**: Magnets are used to extract ferrous metals from the mixture.

**Advantages**: Mechanical separation is relatively simple and cost-effective. It allows for the recovery of metals and plastics without the use of harmful chemicals.

**Limitations**: However, this method may not be effective for recovering all valuable materials, particularly those that require more advanced techniques.

**Case Studies**: Facilities in Europe and North America have successfully implemented mechanical separation processes, achieving high recovery rates for metals.

5. Model 2: Pyrometallurgical Processes

Pyrometallurgical processes involve the use of high temperatures to extract metals from capacitors. This method typically includes smelting, where capacitors are heated in a furnace to separate metals from non-metallic components.

**Benefits**: Pyrometallurgical recycling is effective for recovering precious metals, such as tantalum and gold, which are often found in capacitors.

**Drawbacks**: However, this method can be energy-intensive and may produce harmful emissions if not properly managed. Additionally, it may not be suitable for all types of capacitors.

6. Model 3: Hydrometallurgical Processes

Hydrometallurgical processes utilize chemical solutions to extract metals from capacitors. This method often involves leaching, where capacitors are treated with acids or other solvents to dissolve metals.

**Overview**: Common reagents include sulfuric acid and hydrochloric acid, which selectively dissolve metals while leaving non-metallic components intact.

**Comparison**: Compared to pyrometallurgical methods, hydrometallurgical processes are generally more environmentally friendly, as they operate at lower temperatures and produce fewer emissions. However, they may require more complex processing and handling of chemicals.

7. Model 4: Biotechnological Approaches

Biotechnological methods for recycling capacitors are an emerging field that leverages microorganisms to recover metals. Certain bacteria and fungi can bioleach metals from electronic waste, including capacitors.

**Role of Microorganisms**: These microorganisms can metabolize metals, converting them into soluble forms that can be easily extracted.

**Advantages**: Biotechnological approaches are often more sustainable and environmentally friendly than traditional methods. They can operate at ambient temperatures and may require less energy.

8. Model 5: Direct Recycling

Direct recycling methods aim to reuse capacitors without extensive processing. This approach focuses on refurbishing and repairing capacitors to extend their lifespan.

**Benefits**: Direct recycling reduces waste and conserves resources by keeping functional components in use. It is particularly effective for high-value capacitors, such as those used in renewable energy applications.

**Examples**: Companies specializing in electronic repair and refurbishment have successfully implemented direct recycling programs, contributing to a circular economy.

9. Model 6: Closed-Loop Recycling

Closed-loop recycling refers to systems where materials are recycled back into the same product or process. In the context of capacitors, this means reclaiming materials to produce new capacitors.

**How It Works**: Closed-loop systems involve collecting used capacitors, processing them to recover materials, and then using those materials to manufacture new capacitors.

**Case Studies**: Some manufacturers have adopted closed-loop recycling programs, significantly reducing their reliance on virgin materials and minimizing waste.

10. Model 7: Upcycling and Repurposing

Upcycling involves transforming waste materials into new products with higher value. In the case of capacitors, this can include repurposing them for alternative applications.

**Innovative Uses**: Examples of upcycled capacitors include using them in art installations, DIY electronics projects, or as components in new devices.

**Benefits**: Upcycling not only reduces waste but also fosters creativity and innovation in product design.

11. Model 8: E-Waste Recycling Facilities

Specialized e-waste recycling facilities play a crucial role in the recycling of capacitors. These facilities are equipped with advanced technologies and processes to handle electronic waste safely and efficiently.

**Overview**: E-waste recycling facilities typically employ a combination of mechanical, pyrometallurgical, and hydrometallurgical methods to recover materials from capacitors and other electronic components.

**Importance of Certification**: Compliance with environmental standards and certifications, such as R2 or e-Stewards, ensures that these facilities operate responsibly and minimize their environmental impact.

12. Model 9: Collaborative Recycling Programs

Collaborative recycling programs involve partnerships between manufacturers, recyclers, and consumers to improve recycling rates and promote sustainable practices.

**Successful Initiatives**: Examples include take-back programs where manufacturers collect used capacitors from consumers for recycling, as well as industry-wide initiatives to standardize recycling processes.

**Benefits of Collaboration**: Collaborative efforts can enhance awareness of recycling options, streamline processes, and ultimately lead to higher recovery rates.

13. Model 10: Research and Development in Recycling Technologies

Ongoing research and development are essential for improving recycling methods and technologies. Innovations in materials science, chemistry, and engineering can lead to more efficient and sustainable recycling processes.

**Emerging Technologies**: New techniques, such as advanced separation technologies and improved biotechnological methods, hold promise for enhancing the recycling of capacitors.

**Future Trends**: As the demand for electronic devices continues to grow, the need for effective recycling solutions will become increasingly important. Investment in research and development will be crucial for addressing these challenges.

Conclusion

Recycling capacitors is vital for environmental sustainability and resource recovery. The ten models discussed in this article highlight the diverse approaches available for recycling mainstream capacitors, each with its own advantages and challenges. As the electronics industry continues to evolve, it is essential for manufacturers, consumers, and policymakers to support recycling initiatives and invest in innovative technologies. By doing so, we can ensure a more sustainable future for electronics and contribute to a circular economy.

References

- [WEEE Directive](https://ec.europa.eu/environment/waste/weee/index_en.htm)

- [R2 Certification](https://sustainableelectronics.org/r2/)

- [e-Stewards Certification](https://e-stewards.org/)

- Various academic papers and industry reports on capacitor recycling and electronic waste management.