Precautions for training AC capacitor products

Precautions for Training AC Capacitor Products

I. Introduction

A. Definition of AC Capacitors

AC capacitors are electrical components that store and release electrical energy in alternating current (AC) circuits. They play a crucial role in various applications, including power factor correction, motor starting, and filtering. By temporarily storing energy, capacitors help stabilize voltage and improve the efficiency of electrical systems.

B. Importance of Training in AC Capacitor Products

Training in AC capacitor products is essential for ensuring that technicians, engineers, and other personnel understand the complexities of these components. Proper training not only enhances the knowledge base of the workforce but also promotes safety, efficiency, and compliance with industry standards. As technology evolves, ongoing education becomes increasingly important to keep pace with new developments and best practices.

C. Purpose of the Document

This document aims to outline the precautions necessary for training on AC capacitor products. By providing a structured approach to training, we can ensure that all participants are well-equipped to handle AC capacitors safely and effectively.

II. Understanding AC Capacitors

A. Basic Principles of AC Capacitors

1. Functionality in AC Circuits

AC capacitors function by storing electrical energy in an electric field. When connected to an AC circuit, they charge and discharge in sync with the alternating current, allowing them to smooth out voltage fluctuations and improve overall circuit performance.

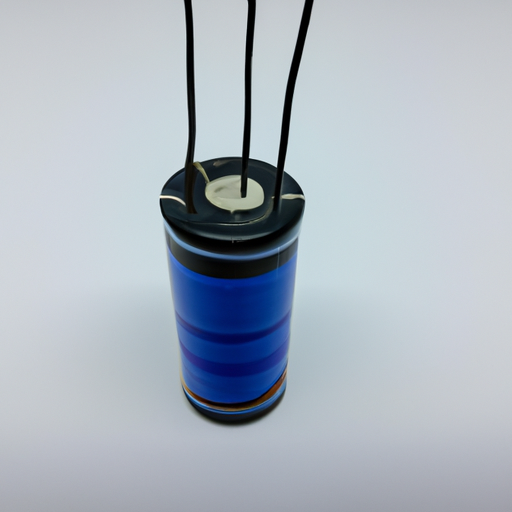

2. Types of AC Capacitors

There are several types of AC capacitors, including:

Film Capacitors: Known for their reliability and stability, these capacitors are commonly used in power factor correction and motor applications.

Electrolytic Capacitors: These capacitors are polarized and typically used in applications requiring high capacitance values.

Ceramic Capacitors: Often used in high-frequency applications, ceramic capacitors are known for their small size and low cost.

B. Applications of AC Capacitors

1. Power Factor Correction

AC capacitors are widely used in power factor correction systems to improve the efficiency of electrical systems. By reducing reactive power, they help lower energy costs and improve the overall performance of electrical equipment.

2. Motor Start and Run Capacitors

In electric motors, capacitors are used to provide the necessary starting torque and to maintain efficient operation during running. Start capacitors provide a boost during startup, while run capacitors help improve the motor's efficiency.

3. Filtering and Smoothing Applications

AC capacitors are also used in filtering applications to smooth out voltage ripples in power supplies, ensuring a stable output voltage for sensitive electronic devices.

III. Safety Precautions

A. General Safety Guidelines

1. Personal Protective Equipment (PPE)

When working with AC capacitors, it is crucial to wear appropriate personal protective equipment (PPE). This includes safety goggles, gloves, and insulated tools to protect against electrical shock and other hazards.

2. Electrical Safety Protocols

Adhering to electrical safety protocols is essential. This includes ensuring that all equipment is properly grounded, using lockout/tagout procedures when servicing equipment, and following all relevant electrical codes and standards.

B. Handling and Storage

1. Proper Storage Conditions

AC capacitors should be stored in a cool, dry environment away from direct sunlight and extreme temperatures. Proper storage conditions help prevent degradation and ensure the longevity of the components.

2. Safe Handling Techniques

When handling capacitors, it is important to avoid dropping or mishandling them, as physical damage can lead to failure. Always handle capacitors by their terminals and avoid touching the conductive parts.

C. Discharge Procedures

1. Importance of Discharging Capacitors

Before working on any circuit containing capacitors, it is vital to discharge them to prevent electrical shock. Capacitors can retain a charge even after power is removed, posing a significant risk to personnel.

2. Safe Discharge Methods

To safely discharge a capacitor, use a resistor to connect the terminals and allow the charge to dissipate gradually. Always verify that the capacitor is fully discharged using a multimeter before proceeding with any work.

IV. Training Program Structure

A. Objectives of the Training Program

The primary objectives of the training program are to enhance participants' understanding of AC capacitors, promote safe handling practices, and ensure compliance with industry standards.

B. Target Audience

The training program is designed for various personnel, including:

1. Technicians

Technicians who install and maintain AC capacitors will benefit from hands-on training and practical applications.

2. Engineers

Engineers involved in the design and specification of AC capacitor systems will gain valuable insights into best practices and troubleshooting techniques.

3. Sales and Marketing Personnel

Sales and marketing teams will learn about the technical aspects of AC capacitors to better communicate their benefits to customers.

C. Training Modules

The training program will consist of several modules, including:

1. Theoretical Knowledge

Participants will learn about the fundamental principles of AC capacitors, their types, and applications.

2. Practical Applications

Hands-on training will allow participants to work with AC capacitors, reinforcing their understanding of installation and maintenance practices.

3. Troubleshooting Techniques

Participants will be trained in common troubleshooting techniques to identify and resolve issues related to AC capacitors.

V. Key Training Content

A. Understanding Specifications and Ratings

1. Voltage Ratings

Participants will learn about the importance of voltage ratings and how to select capacitors that meet the requirements of their specific applications.

2. Capacitance Values

Understanding capacitance values is crucial for selecting the right capacitor for a given application. Participants will learn how to interpret capacitance ratings and their implications for circuit performance.

3. Temperature Ratings

Temperature ratings indicate the operating limits of capacitors. Participants will learn how to choose capacitors that can withstand the environmental conditions of their applications.

B. Installation Best Practices

1. Correct Wiring Techniques

Proper wiring techniques are essential for ensuring the safe and efficient operation of AC capacitors. Participants will learn about wiring diagrams and best practices for connecting capacitors in circuits.

2. Mounting and Placement Considerations

The placement of capacitors can impact their performance. Participants will learn about mounting techniques and placement considerations to optimize capacitor function.

C. Maintenance and Inspection

1. Regular Maintenance Schedules

Establishing regular maintenance schedules is vital for ensuring the longevity and reliability of AC capacitors. Participants will learn how to create and implement effective maintenance plans.

2. Signs of Wear and Failure

Participants will be trained to recognize signs of wear and potential failure in AC capacitors, enabling them to take proactive measures to prevent issues.

VI. Common Mistakes and Misconceptions

A. Overloading Capacitors

One common mistake is overloading capacitors beyond their rated specifications. Participants will learn the importance of adhering to manufacturer guidelines to prevent damage and ensure safe operation.

B. Ignoring Manufacturer Guidelines

Ignoring manufacturer guidelines can lead to improper installation and increased risk of failure. Participants will be educated on the importance of following these guidelines closely.

C. Misunderstanding Capacitor Behavior in Circuits

A common misconception is that capacitors can be treated like resistors. Participants will learn about the unique behavior of capacitors in AC circuits and how to account for this in their designs and applications.

VII. Evaluation and Feedback

A. Assessing Training Effectiveness

1. Pre- and Post-Training Assessments

To evaluate the effectiveness of the training program, pre- and post-training assessments will be conducted to measure knowledge gains.

2. Feedback Mechanisms

Participants will be encouraged to provide feedback on the training program, allowing for continuous improvement and refinement of the content.

B. Continuous Improvement

1. Updating Training Materials

Training materials will be regularly updated to reflect new technologies, standards, and best practices in the industry.

2. Incorporating New Technologies and Standards

As the field of AC capacitors evolves, the training program will incorporate new technologies and standards to ensure participants remain informed and competent.

VIII. Conclusion

A. Recap of Key Points

In summary, training on AC capacitor products is essential for ensuring safety, efficiency, and compliance in electrical systems. By understanding the principles, applications, and best practices associated with AC capacitors, personnel can enhance their skills and contribute to the success of their organizations.

B. Importance of Ongoing Education and Training

Ongoing education and training are vital in a rapidly changing technological landscape. By committing to continuous learning, professionals can stay ahead of industry trends and advancements.

C. Encouragement for Safe Practices in AC Capacitor Handling and Training

Finally, it is crucial to prioritize safety in all aspects of AC capacitor handling and training. By following established guidelines and protocols, personnel can minimize risks and ensure a safe working environment.

IX. References

A. Industry Standards and Guidelines

- National Electrical Manufacturers Association (NEMA)

- Institute of Electrical and Electronics Engineers (IEEE)

B. Recommended Reading and Resources

- "Capacitors: Technology and Applications" by John Smith

- "Electrical Safety Handbook" by John Cadick

C. Contact Information for Further Inquiries

For further inquiries or additional resources, please contact [Your Organization's Contact Information].

---

This blog post provides a comprehensive overview of the precautions necessary for training on AC capacitor products, ensuring that the content is educational and informative for the target audience. By following these guidelines, organizations can enhance the safety and effectiveness of their training programs.