Latest capacitor medium specifications

Latest Capacitor Medium Specifications

I. Introduction

A. Definition of Capacitors

Capacitors are passive electronic components that store and release electrical energy in a circuit. They consist of two conductive plates separated by an insulating material known as a dielectric. When voltage is applied across the plates, an electric field is created, allowing the capacitor to store energy. Capacitors are essential in various electronic applications, from filtering signals to energy storage.

B. Importance of Capacitor Specifications

Understanding capacitor specifications is crucial for engineers and designers. The performance, reliability, and suitability of a capacitor for a specific application depend on its specifications. Selecting the right capacitor can significantly impact the efficiency and longevity of electronic devices. Therefore, a comprehensive understanding of the latest capacitor medium specifications is vital for anyone involved in electronics design and manufacturing.

C. Overview of the Document's Purpose

This document aims to provide an in-depth overview of the latest capacitor medium specifications, including types of capacitors, key specifications, recent technological advances, applications, and guidelines for selecting the right capacitor. By the end of this article, readers will have a clearer understanding of capacitors and their specifications, enabling them to make informed decisions in their projects.

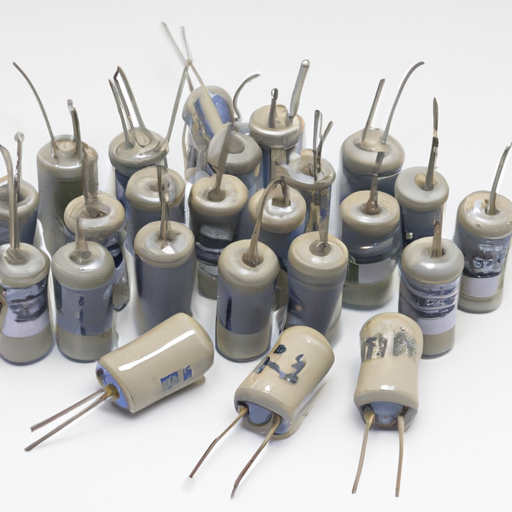

II. Types of Capacitors

Capacitors come in various types, each with unique characteristics and applications. Here, we will explore the most common types of capacitors.

A. Electrolytic Capacitors

1. Characteristics

Electrolytic capacitors are polarized components that typically offer high capacitance values in a compact size. They use an electrolyte as one of the plates, which allows for a larger surface area and, consequently, higher capacitance.

2. Applications

These capacitors are widely used in power supply circuits, audio equipment, and energy storage applications due to their ability to handle large amounts of charge.

B. Ceramic Capacitors

1. Characteristics

Ceramic capacitors are non-polarized and made from ceramic materials. They are known for their stability, low ESR, and high-frequency performance. Their capacitance values can vary widely, but they are generally smaller than electrolytic capacitors.

2. Applications

Commonly used in decoupling and filtering applications, ceramic capacitors are prevalent in consumer electronics, telecommunications, and automotive systems.

C. Film Capacitors

1. Characteristics

Film capacitors use a thin plastic film as the dielectric. They are known for their excellent stability, low ESR, and high voltage ratings. Film capacitors are non-polarized and can handle high-frequency signals effectively.

2. Applications

These capacitors are often used in audio equipment, power electronics, and applications requiring high reliability and stability.

D. Tantalum Capacitors

1. Characteristics

Tantalum capacitors are also polarized and offer high capacitance in a small package. They are known for their reliability and stability, making them suitable for critical applications.

2. Applications

Tantalum capacitors are commonly used in military, aerospace, and medical devices, where reliability is paramount.

E. Supercapacitors

1. Characteristics

Supercapacitors, or ultracapacitors, have extremely high capacitance values and can store large amounts of energy. They bridge the gap between traditional capacitors and batteries, offering rapid charge and discharge capabilities.

2. Applications

Supercapacitors are used in applications requiring quick bursts of energy, such as regenerative braking systems in electric vehicles and energy storage in renewable energy systems.

III. Key Specifications of Capacitors

When selecting a capacitor, several key specifications must be considered to ensure optimal performance.

A. Capacitance Value

1. Measurement Units (Farads, Microfarads, etc.)

Capacitance is measured in farads (F), with common subunits including microfarads (µF) and picofarads (pF). The capacitance value indicates the amount of charge a capacitor can store.

2. Tolerance Levels

Tolerance refers to the allowable deviation from the nominal capacitance value. It is crucial to consider tolerance levels, especially in precision applications.

B. Voltage Rating

1. Importance of Voltage Rating

The voltage rating indicates the maximum voltage a capacitor can handle without breaking down. Exceeding this rating can lead to catastrophic failure.

2. Derating Guidelines

It is advisable to derate capacitors by 20-50% of their voltage rating in practical applications to enhance reliability and longevity.

C. Equivalent Series Resistance (ESR)

1. Definition and Importance

ESR is the internal resistance of a capacitor that affects its performance, especially in high-frequency applications. Lower ESR values are generally preferred for better efficiency.

2. Impact on Performance

High ESR can lead to power loss and heat generation, impacting the overall performance of the circuit.

D. Temperature Coefficient

1. Explanation of Temperature Coefficient

The temperature coefficient indicates how a capacitor's capacitance changes with temperature. It is essential for applications where temperature variations are expected.

2. Types (X7R, C0G, etc.)

Different types of temperature coefficients, such as X7R and C0G, offer varying levels of stability and performance across temperature ranges.

E. Lifetime and Reliability

1. Factors Affecting Lifetime

The lifetime of a capacitor can be influenced by factors such as temperature, voltage, and ripple current. Understanding these factors is crucial for ensuring long-term reliability.

2. Reliability Testing Standards

Various industry standards exist for testing capacitor reliability, including MIL-PRF-39006 and IEC 60384. Adhering to these standards can help ensure the quality and longevity of capacitors.

IV. Recent Advances in Capacitor Technology

The capacitor industry has seen significant advancements in recent years, driven by the demand for higher efficiency and performance.

A. Development of High-Efficiency Capacitors

Manufacturers are focusing on creating capacitors with lower ESR and higher capacitance values, improving overall efficiency in electronic circuits.

B. Innovations in Materials Used

1. Nanotechnology in Capacitors

Nanotechnology is being explored to enhance the performance of capacitors, allowing for smaller sizes and higher capacitance values.

2. Biodegradable Capacitors

With increasing environmental concerns, research is underway to develop biodegradable capacitors that reduce electronic waste.

C. Trends in Miniaturization

As electronic devices become smaller and more compact, the trend toward miniaturization in capacitor design continues, enabling more efficient use of space in circuits.

D. Smart Capacitors and IoT Integration

The integration of capacitors with smart technology and IoT applications is on the rise, allowing for real-time monitoring and enhanced performance in various applications.

V. Applications of Capacitors in Modern Technology

Capacitors play a vital role in numerous modern technologies, including:

A. Consumer Electronics

From smartphones to televisions, capacitors are essential for power management, signal filtering, and energy storage in consumer electronics.

B. Automotive Industry

Capacitors are used in various automotive applications, including power supply systems, audio equipment, and advanced driver-assistance systems (ADAS).

C. Renewable Energy Systems

In renewable energy systems, capacitors are crucial for energy storage, smoothing out fluctuations in power generation, and improving overall system efficiency.

D. Telecommunications

Capacitors are integral to telecommunications equipment, providing filtering and decoupling functions to ensure signal integrity.

E. Industrial Automation

In industrial automation, capacitors are used in motor drives, power supplies, and control systems, enhancing performance and reliability.

VI. Selecting the Right Capacitor

Choosing the right capacitor for a specific application requires careful consideration of several factors.

A. Factors to Consider

1. Application Requirements

Understanding the specific requirements of the application, such as capacitance value, voltage rating, and ESR, is essential for selecting the appropriate capacitor.

2. Environmental Conditions

Consideration of environmental factors, such as temperature and humidity, can impact the performance and reliability of the chosen capacitor.

B. Common Mistakes in Selection

Common mistakes include overlooking voltage ratings, ignoring tolerance levels, and failing to consider the impact of temperature on performance.

C. Resources for Further Research

Numerous resources are available for further research, including manufacturer datasheets, industry standards, and academic journals.

VII. Conclusion

A. Summary of Key Points

In summary, understanding the latest capacitor medium specifications is crucial for anyone involved in electronics design and manufacturing. By familiarizing oneself with the various types of capacitors, key specifications, recent advancements, and applications, one can make informed decisions in selecting the right capacitor for specific needs.

B. Future Trends in Capacitor Technology

As technology continues to evolve, we can expect further advancements in capacitor technology, including improved materials, enhanced performance, and greater integration with smart technologies.

C. Final Thoughts on the Importance of Understanding Capacitor Specifications

In conclusion, a thorough understanding of capacitor specifications is essential for ensuring the reliability and efficiency of electronic devices. As the demand for high-performance capacitors grows, staying informed about the latest developments in capacitor technology will be crucial for engineers and designers alike.

VIII. References

A. Academic Journals

- IEEE Transactions on Electron Devices

- Journal of Applied Physics

B. Industry Standards and Guidelines

- MIL-PRF-39006

- IEC 60384

C. Manufacturer Specifications and Datasheets

- Manufacturer websites and product datasheets provide valuable information on specific capacitor models and their specifications.